Executive Summary

In response to a client’s request to evaluate the feasibility of monitoring methane emissions outside hazardous classification zones, GLX Technologies delivered a custom, field -deployable prototype in just 10 weeks.

Leveraging simulations, sensor evaluations, and rapid iterative design, the GLX Professional Services team built and deployed eight continuous emissions monitoring systems (CEMS) to support real -world testing. The fast -prototype engagement allowed the client to validate methane detection capabilities, assess technical viability, and inform future production decisions —without the cost or delay of a full -scale system.

This case study illustrates how GLX enables clients to accelerate learning, reduce risk, and explore innovative solutions through rapid prototyping.

1.0 Introduction

At GLX Technologies (GLX) , we help Oil & Gas and Water Utility clients explore what’s possible — fast. When a client asked whether methane emissions could be effectively monitored outside hazardous classification zones, our Professional Services team responded with a rapid feasibility project. In just 10 weeks, we designed, built, and delivered eight prototype continuous emissions monitoring systems (CEMS) to support field validation.

Rather than committing to a production -grade solution up front, the client leveraged our fast -prototype model to gain real -world insights quickly - evaluating sensor performance, system design, and installation strategies without full -scale investment. This case study highlights how GLX enables innovation with speed and purpose. When timelines are tight and the path forward is uncertain, our Professional Services team helps clients test assumptions, reduce

risk, and make informed decisions.

2.0 Case Study

2.1 Problem

A client in the Oil & Gas sector approached GLX with two targeted questions:

• Can methane emissions be reliably detected from outside the site’s hazardous classification

zones ?

• Can this be done for less than current commercial solutions and without a recurring

subscription ?

Existing methane -sensing solutions required equipment installation within the classified area - adding cost, complexity, and regulatory burden. These solutions often come with recurring subscriptions and requirements for visualization on proprietary systems. Furthermore, camera solutions are effective, but represent a significant cost per site, and may be overkill for their numerous small sites that require detection. The client was interested in exploring an alternative monitoring approach that could be

deployed outside the classification boundary and be interfaced to their SCADA system s without a recurring subscription , but needed practical evidence before moving forward with full system development.

With limited precedent and a narrow decision window, the client engaged the GLX Professional Services team to rapidly prototype and field test a custom solution — allowing them to assess technical feasibility before committing to a production or alternative path.

2.2 Solution

GLX proposed a phased, fast -prototype engagement structured around three core objectives:

- Simulate and evaluate sensor candidates for methane plume detection outside the hazard zone

- Scope, design , and build a field -deployable prototype with representative components and telemetry

- Deploy and test the systems on -site to determine feasibility and inform next steps

This approach prioritized speed, flexibility, and iterative learning — ideal for gaining actionable insights without requiring full -system investment.

2.2.1 Sensor Evaluation and Simulations

The GLX team began by modeling methane dispersion under various environmental and release conditions to estimate expected concentrations outside the hazard boundary. Based on these results, we shortlisted multiple sensors (Figaro 2600, 2611, 8410, and Ferm ion MEMS) for testing in the CEMS

prototype .

Performance factors included:

• Sensitivity to target methane ranges

• Response time

• Environmental robustness

• Integration compatibility

(a) |

(b) |

(c) |

(d) |

Figure 1. Sensors evaluated : a) Figaro 26 00, b) Figaro 26 11, c) Figaro 84 10, d) Fermion MEMS .

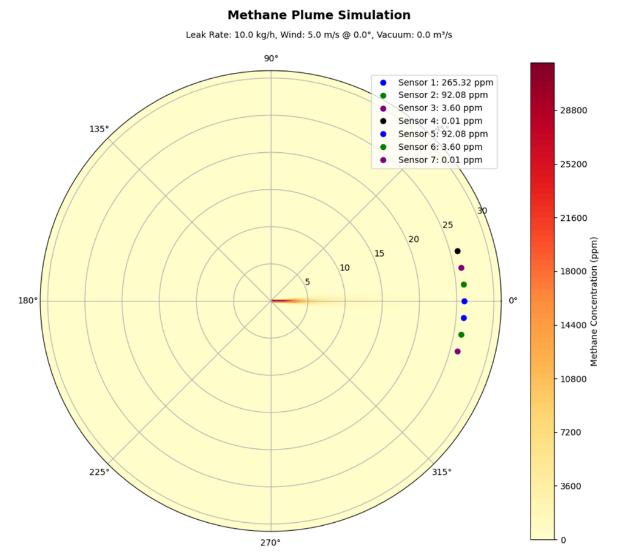

Simulations were used to identify optimal sensor placement and determine whether measurable detection would be viable under real -world site conditions that will be impacted by varying leak rates and wind conditions.

Figure 2. Methane plume simulation.

2.2.2 Prototype

Using insights from the evaluation phase, GLX designed and built eight prototype monitoring units, each equipped with:

• Selected methane sensors for the field evaluation and a temperature /humidity sensor was included to monitor sample conditions .

• A compact all -in-one RTU (TBox) with LTE communications

• Printed circuit board to interface sensors and vacuum control to RTU

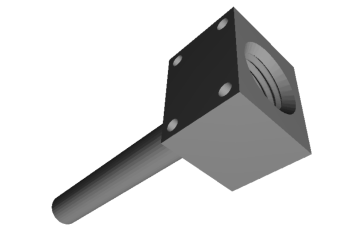

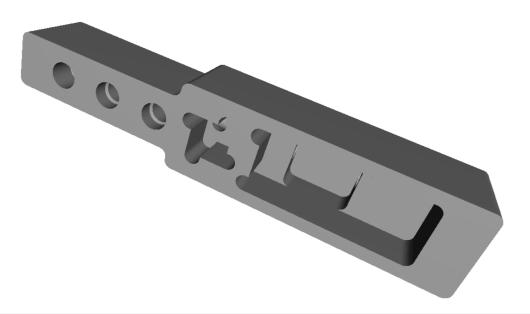

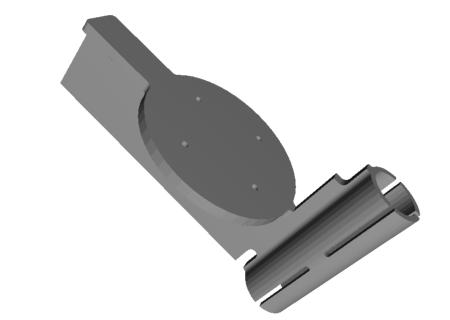

• 3D-printed manifold for housing methane sensors

• 3D-printed sampling port providing protection from water, dust, and insect intake

• 3D-printed weather station mounts

• IP67 enclosures

• Solar and LiFePO₄ battery power systems

The prototype performance scope was limited to developing a “smoke detector” capability – logging real-time analog measurements of methane accessible over a cellular network for the client to ingest in a third -party developed Grafana dashboard for visualization. Quantification of the methane levels were out of scope for the current prototype .

The client identified a small site where the 8 CEMS prototypes would be deployed and distributed uniformly outside the perimeter of the classified zone s maximizing the opportunity to test the sensors in different wind conditions. The client worked with 3rd parties to deploy commercially available systems to provide a benchmark and control for the evaluation – these included systems designed for point detection within the classification as well as a shortwave infrared camera .

All units were developed in under 10 weeks – from concept through assembly and QA – and delivered to the client for installation on their own poles and skids outside the classification zones. This project highlighted the diverse capabilities of the GLX Professional Services team :

1. Conceptual drawings were quickly 3D modeled and printed for form, fit, and function testing allowing for quick iterations. These included the sampling ports , sensor manifold, and weather station mounts – all designed to interface to standard fittings.

|  |  |

|  |

|  |